In the quest for sustainable and reliable energy solutions, heat pumps have taken center stage. This technology reshapes how industries and communities meet their heating needs, which account for 50%~ of the world’s energy end-use.

This article will explain the basics of water-heating heat pumps, discuss how they can replace fossil fuels in industrial and commercial heat processes, and benefit from integration with thermo-solar systems.

Heat Pumps – Technology Overview

Heat pumps are heating/cooling technology that transfer heat from one area to another. Moving heat instead of generating it (by burning fossil fuels, for example) makes heat pumps 3-4 times more energy efficient than traditional heating methods.

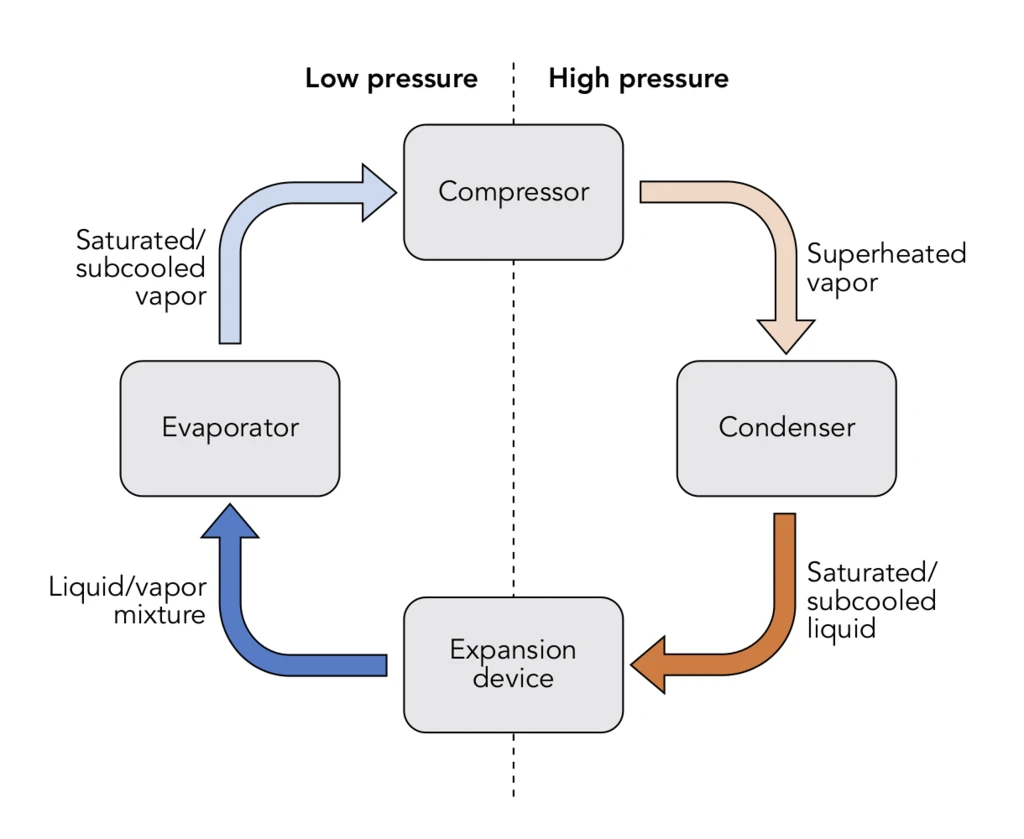

The main components of water-heating heat pumps are a compressor, a condenser, an evaporator, and an expansion valve.

As heat naturally flows from areas of higher temperature to ones of lower temperature, and the temperature of gas increases as it is compressed and decreases as it expands, in heating mode, a heat pump’s cycle works as follows:

- A refrigerant in an evaporator absorbs heat from a heat source (air, ground, waste industrial heat, etc.) and evaporates into a gas.

- The gas is compressed to increase its temperature and pressure.

- The hot gas is moved through a condenser inside a water tank, releasing heat and heating the water while liquefying.

- The refrigerant is then moved through an expansion valve to expand and cool off further.

- The cold refrigerant goes into the evaporator to begin the process all over again.

Thus, by leveraging a small amount of external energy, heat pumps extract and amplify heat from the surrounding environment, making them an eco-friendly alternative to conventional heating methods.

Russia’s invasion of Ukraine, climate change, and technological improvements accelerate heat pumps’ adoption.

Since Russia’s invasion of Ukraine, governments, municipalities, and hundreds of thousands of factories all over Europe are exploring the possibility of using heat pumps to replace heat systems based on natural gas.

This transition not only reduces carbon emissions but also enhances operational efficiency. New regulations that cap the use of fossil fuels and give incentives to more efficient technologies make heat pumps exceptionally cost-effective.

Furthermore, more efficient and sustainable refrigerants emerge as heat pump technology advances. New synthetic refrigerants with lower Global Warming Potential (GWP) significantly reduce greenhouse gas emissions compared to their traditional counterparts. Natural refrigerants for industrial heat pumps, such as carbon dioxide, ammonia and propane, offer a greener alternative by boasting minimal environmental impact.

Replacing Traditional Fossil Fuels In Industrial And Commercial Heat Processes.

High-temperature heat pumps for industrial applications constantly push the technological limits higher. Such heat pumps are positioned to replace conventional fossil fuel-based heating processes in factories, such as steam systems, presenting a revolutionary shift in industrial energy usage. These Heat pumps offer an energy-efficient alternative to traditional steam-based heat systems by delivering heat effectively at elevated temperatures.

This shift translates to reduced operational costs, decreased reliance on fossil fuels, and a notable reduction in greenhouse gas emissions. The adaptability of high-temperature heat pumps showcases their potential to reshape industrial processes more sustainably.

Harnessing Enormous Heat Pump Potential for District Heating

District heating systems powered by enormous heat pumps can reshape urban energy landscapes and foster efficient, large-scale heat distribution.

District heating supplies heat to multiple buildings through a centralized system, offering a more efficient alternative to individual heating units. Heat pumps’ capacity to produce substantial amounts of heat contributes to cost-effective and sustainable district heating solutions.

District heating projects become even more environmentally friendly and economically viable by seamlessly combining heat pump technology with renewable heat inputs such as thermo-solar systems and electricity production from solar, wind or geothermal sources.

Integrating heat pumps with thermo-solar and storage systems for industrial and municipal applications

Integrating heat pumps with thermo-solar systems and thermal energy storage (TES) creates a considerable synergy by amplifying the effectiveness of those technologies. An Industrial water heating system combining thermal-solar collectors, heat pumps, TES, and an advanced control system can supply big heat consumers such as industry and district heating with all the heat they need without relying on expensive, polluting, and unreliable fossil fuels.

Thermal-solar collectors and industrial heat pumps using renewable electricity from PV or wind turbines are extremely clean, efficient, and cost-effective. The only issue is intermittency. By adding storage and advanced controls, such an integrated system can provide 24/7 cheap and sustainable hot water to factories, hotels, agriculture plants, big government facilities (hospitals, military bases, etc.), whole districts, and more.

Unlocking Tomorrow’s Energy Solutions with TIGI Solar

In a world seeking innovative energy solutions, TIGI Solar’s system can be the answer with its comprehensive system –

- Patented solar thermal collectors that work efficiently in hot and cold climates

- Extremely energy efficient Industrial-grade heat pumps.

- Smart hot water storage.

- An advanced cloud-based control system managing and optimizing heat processes remotely, ensuring efficiency, cost-effectiveness, and sustainability.

Working with the HaaS (Heat as a Service) model, TIGI Solar offers more than just technology; it provides a holistic heat solution. No upfront costs, immediate savings, and hassle-free maintenance that redefine how businesses harness heat.

As industries move away from costly and geo-politically unreliable fossil fuels towards sustainable practices, partnering with TIGI Solar becomes an opportunity to lead the change.

Contact our team today to learn more about TIGI’s advanced, sustainable, holistic commercial and industrial heat solution.